TAP FEEDS & SPEEDS

How to Tap Effectively and Optimize Tool Life To minimize tapping issues the following rules should be followed:

• Use a pitch controlled tapping attachment.

• Choose the correct lubricant (Choose – Ultra S/P ™ Super Premium).

• Use the correct tapping drill size and type of tap.

• Choose the correct Speeds and Feeds.

• Keeping taps sharp, check tap for wear.

• Ensure accurate alignment.

• Check hardness of material, especially when changing batches of material.

Tapping Speed can be calculated using: (Use Table below)

RPM = Feed Speed (SFM) / 0.26 x Tap's Outer Dimension

Tapping speeds should be " DECREASED " if

• Lubricant is Poor or Flow is Restricted.

• Bottom lead or Spiral flute taps are used.

• Thread depth ( % ) increase.

• Thread pitch is course.

• Cutting taper threads (50% Normal Speed).

Tapping speeds can be " INCREASED " if

• Thread Depth decreases.

• Thread Pitch is fine.

• Coolant flow and Quality is Good.

• Spiral point taps are used.

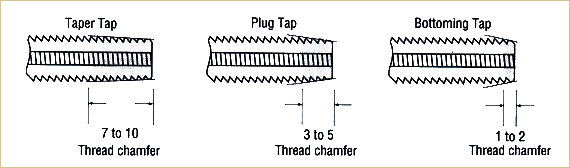

Tapping Speeds Proper tapping speeds are very important in obtaining efficient tapping results. The optimum speed for tapping is highest speed that conditions permit, consistent with acceptable tool life. Speeds must be reduced as length of hole increases. Holes, taps with tapered chamfers are able to operate faster than taps with bottoming chamfers. Vertical tapping speeds can be increased, compared to horizontal tapping.

Recommended Feeds and Speeds table below suggests a "starting point" for selecting the speed to operate the tap.

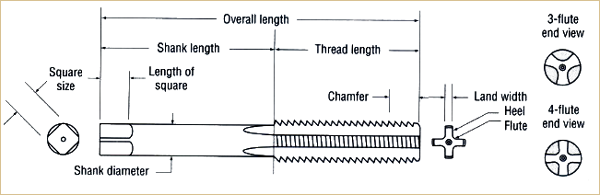

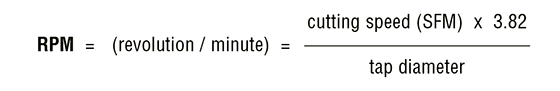

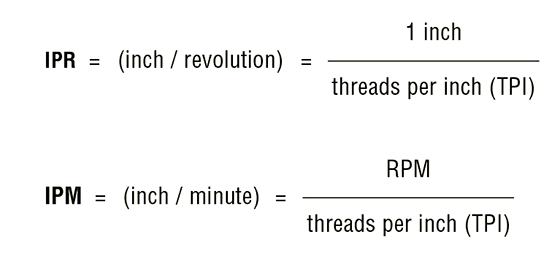

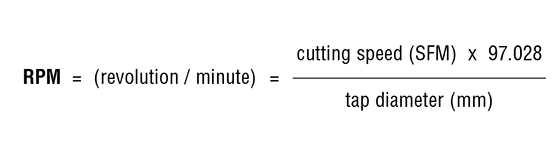

Tapping Formulas and Calculations

RPM for UNC/UNF

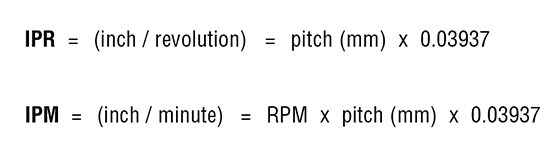

Feed Rate for UNC/UNF Taps

RPM for M/MF Taps

Feed Rate for M/MF Taps

Recommended Feeds and Speeds (SFM) into Material

| Material | Recommended Feeds and Speeds (SFM) |

| Aluminum - Cast Alloys | 60 |

| Aluminum - Diecast Alloys | 70 |

| Aluminum - Wrought Alloys | 80 |

| Brass | 60-100 |

| Bronze | 30-40 |

| Copper | 60-80 |

| Gun Metal | 50-60 |

| Cast Iron - Grey | 30-60 |

| Cast Iron - Ductile | 50 |

| Cast Iron - Alloys | 15-30 |

| Malleable Alloy | 20-40 |

| Magnesium Alloys | 50-70 |

| Nickel Alloys | 10 |

| Nimonic Alloys | 10-12 |

| Mild Steel | 30-50 |

| Steel - Medium Carbon | 35 |

| Tool Steel | 15-25 |

| Cast Steel | 25 |

| Titanium Alloys | 10 |

| Stainless Steel - 300 Series | 10-20 |

| Stainless Steel - 400 Series | 15 |

| Plastic | 50-70 |

| Zinc - Diecasting | 80 |