PRODUCT CATALOG - Viking Drill and Tool

-

Substantially longer cutting life

The nitro-carburized flute has an increased Rockwell hardness.

Holds tighter hole size

The split point design is self centering. This limits the normal oversize drilling characteristics.

Cuts harder materials

The flatter point takes a smaller chip. More torque is directed to a smaller area. This allows drilling into materials with hardness of over 30 on the Rockwell "C" scale.

Runs cooler, uses less torque

135° point takes a smaller chip resulting in less heat. Friction is reduced by amber gold surface treatment.

Stops drill walking

The split point design gives accurate starting without the use of a center punch.

Twist Drills Section

Cryo/Nitride Jobber Length. Super Premium 135° split point drills will substantially outperform cobalt drills in work harding stainless steel applications.

Annular Cutters/MBD Section

Using the latest manufacturing and design technology to provide hole-cutting solutions for a wide range of industries.

Premium Carbide Burrs Section

Double Cut is the most popular burr for ferrous applications. Aluma Cut is used on Aluminum, Non-ferrous metals, Soft steel, Reinforced plastics and other soft materials.

Displays, Cabinets & Indexes Section

Cost effective tool management and storage systems, which eliminates wasted time searching and is the safest way to store sharp tools.

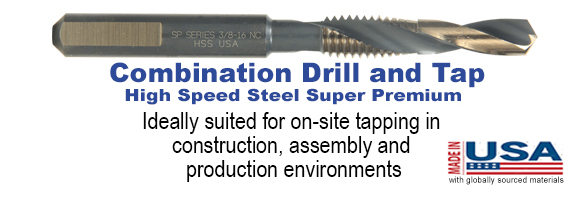

Taps and Dies Section

Titanium Nitride M42 Cobalt Taps. High performance reduced neck with spiral point taps and Straight flute hand taps can be used by hand or tapping under power.

Specialty Tools Section

Introducing VORTEX–POINT™ unique tip geometry. We offer a wide range of specialty tools including: Step Reamers, Left-hand spiral drills, Hex Nut Bridge Reamers.

Cutting Tool Sets Section

RED - Ultra Dex 29pc. Cryogenic Nitrided. Blaze Orange Ultra Dex 29pcs Sets (SP-29PO) - Variety of sizes of sets, ranging from 4 piece tool sets up to 115 piece sets.

Coating Styles Sheet

Coating hardness is measured in HV (Hardness in Vickers) Heat treat M2 as the base drills before coating would measure 880 HV (65RC).