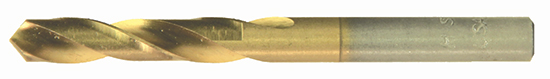

TiN Screw Machine General Purpose

Type 260-BN TiN Screw Machine Length - General Purpose

— This drill is designed for ease of penetration and to facilitate chip removal

in tough, hard materials.

— Performs well in mild drilling applications with abrasive wear characteristics.

— Short length of drill and flute makes this an especially rigid drill for greater

drilling accuracy.

— Titanium Nitride coating for good lubricity, low heat resistance and

extended tool life.

— May also be used in portable drilling equipment.

— Proudly manufactured in the USA

with globally sourced material

PDF — Type 260-BN TiN Screw Machine Length General Purpose

PDF — Type 260-BN TiN Screw Machine Length General Purpose

High-speed steel is highly alloyed tool steel capable of maintaining hardness even at elevated temperatures. High-speed steel is named primarily because of their ability to machine materials at high cutting speeds.

The carbon and alloy contents are balanced at levels to give high achievable hardening response, high wear resistance, high resistance to the softening effect of heat, and good toughness for effective use in industrial cutting operations.

Especially suited to applications involving complicated tool shapes: drills, taps, milling cutters and broaches.

High-speed steel is superior to the older high-carbon steel tools used extensively through the 1940’s in that it can withstand higher temperatures without losing its temper (hardness).